Lessons learned from an open-hardware project in microscopy: The mesoSPIM initiative

Posted by Fabian Voigt, on 1 July 2020

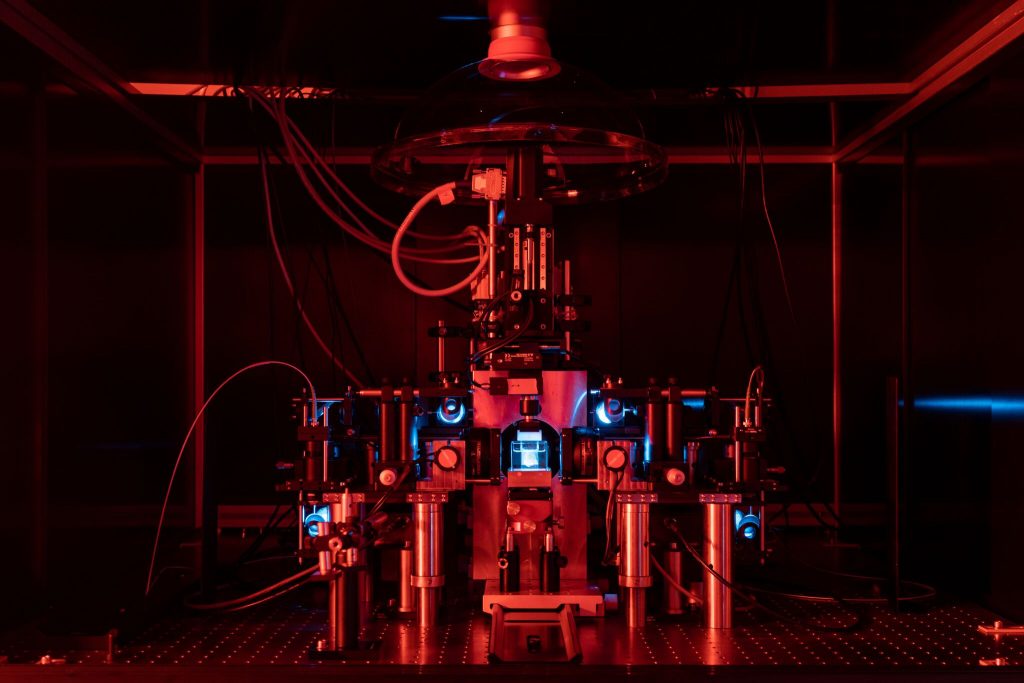

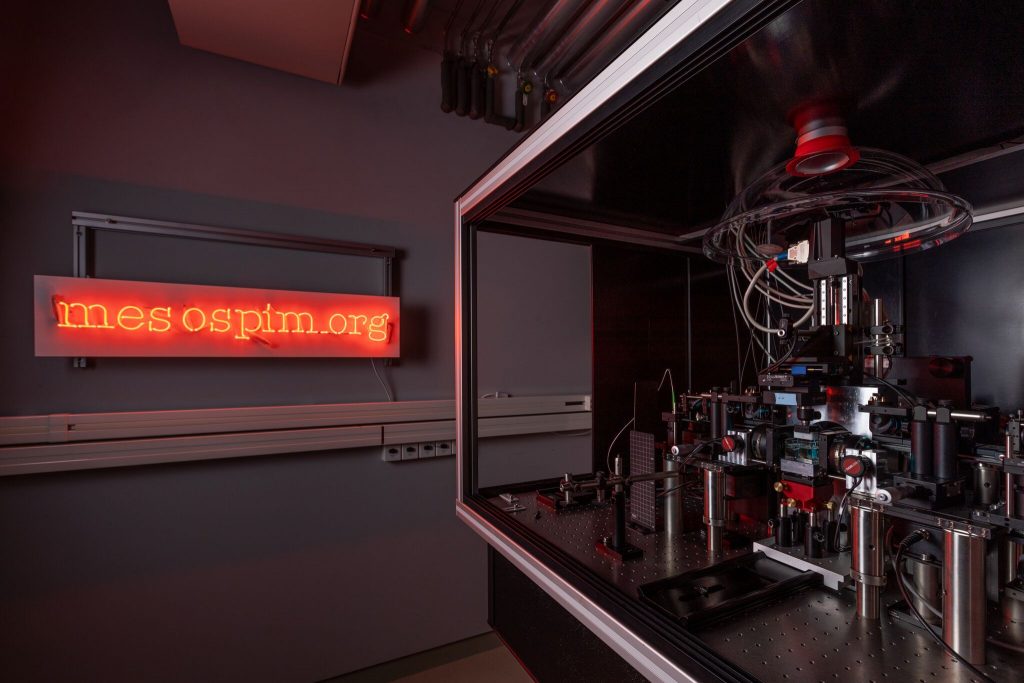

The mesoscale selective plane illumination microscope (mesoSPIM) is a highly versatile open-source light-sheet microscope for imaging large (cm-sized) cleared tissue samples. Using the documentation and software available via mesospim.org and on Github, interested labs can set up their own microscope. Currently, ten mesoSPIM instruments are in operation around the globe and several more are under construction. This post recounts the history of the project and lists a variety of things I wish I had known before starting the project.

“Which commercial light-sheet microscope should we get for our cleared samples?” The question was asked to me by Adriano Aguzzi and his MD-PhD student Daniel Kirschenbaum in early 2015. They were looking for a microscope to image mouse brains cleared with a modified CLARITY technique developed by Daniel. At that time, I had just started my PhD in the lab of Fritjof Helmchen (Brain Research Institute, University of Zurich) and I jumped at the opportunity to work with light-sheet imaging again – a few years prior, I had worked on fast 3D light-sheet microscopy in collaboration with Jan Huisken and thoroughly enjoyed using light-sheets. After evaluating several commercial instruments, we decided that the best way forward was to build a custom instrument. The idea was to combine the best features of the commercial LaVision Ultramicroscope I (namely, the zoom macroscope to achieve large field-of-views (FOVs) of up to 2 cm size and a nice way of reducing shadowing) with the cuvette-based sample mounting and sample rotation capability of the CLARITY-optimized light-sheet microscope (COLM) developed by Raju Tomer. The reason for combining both was that neither microscope was entirely satisfactory for our needs. The Ultramicroscope suffered from unstable software, a limited travel range for our large samples, cumbersome sample handling, and the requirement for large amounts of expensive index-matching solution. On the other hand, the COLM provided excellent image quality but generated too much data: with a maximum FOV of 3.3 mm using a 4x objective, a typical mouse brain resulted in a Terabyte of data! Given that Daniel was ramping up to image hundreds of mouse brains, I feared a data deluge coming. In fact, one of the postdocs whom we visited even mentioned that they were thinking about getting an Ultramicroscope in addition to their COLM because they were swamped by the data coming off the microscope. In light of this remark, I decided: “I’m happy to build a COLM in Zurich, but let’s build a large-FOV light-sheet first”.

In October 2015, my first clearing light-sheet microscope was operational, and over the course of the upcoming years I improved the system with better hard- and software. In July 2017, I set up the second mesoSPIM in the Aguzzi lab at the University Hospital Zurich. Up to this point, I saw the mesoSPIM as a side project that was more of a distraction, a view that changed when in mid-2017 the Wyss Center for Bio and Neuroengineering, a non-profit neurotechnology hub in Geneva, expressed interest in getting a mesoSPIM for their imaging facility. I immediately thought, if this facility is interested, surely, other labs must be interested as well! This event led me to stop thinking about the mesoSPIM as a side project and to consider it as the core project of my PhD – something that was totally fine with my PhD supervisor. I also entertained the idea of turning the mesoSPIM into a startup, but I analyzed the emerging small microscopy companies and realized that, while it is totally feasible to start a microscope company for academic customers, it is very difficult to grow one into a large business – the market is simply not large enough. In addition, the idea of turning the mesoSPIM into an open-hardware project was something that aligned more with my values. However, it would require a massive effort to turn a cobbled-together microscope (using parts scavenged from past projects) into something reasonably well-documented that others could copy, an issue I started to tackle in late 2017. At the same time, Laura Batti and Stéphane Pagès of the Wyss imaging team came up with the idea of hosting a Swiss Light-sheet Microscopy Workshop in Geneva on March 19th & 20th 2018. This event would be a perfect platform to showcase the mesoSPIM – provided that the Wyss microscope was up and running at that time…

This turned out to be a frantic last-minute effort. On March 14th, Evgenia Platonova from the Center for Microscopy and Data Analysis of the University of Zurich (who would go on build the next setup) and I went to Geneva to build mesoSPIM #3. Despite minor hickups with delayed hardware deliveries, everything went fine and on March 19th, we could demonstrate the mesoSPIM to a large audience at the workshop. After this meeting, more and more groups expressed interest, and by the time we uploaded the mesoSPIM preprint [1] in March 2019, five mesoSPIM instruments were already operational across Europe. A few months after the mesoSPIM paper was published in Nature Methods in October 2019 [2], that number had increased to ten.

While these numbers are not striking compared to other open-source microscopes (for example, there seem to be around 150 openSPIM instruments), it should be noted that the mesoSPIM falls under a category that I call “premium” open hardware: a mesoSPIM typically costs 150,000 -250,000 €, which is a significant budget compared to other open hardware projects. It is intended to be a multi-user instrument that can be run by a facility. In terms of sample size and versatility, it outclasses any current-generation commercial light-sheet microscope, many of which are far more expensive. Therefore, the mesoSPIM occupies a vastly different niche compared to open microscopes intended to be educational tools or designed for low-resource settings.

With this orientation towards the premium open hardware segment in mind, below, I’m happy to share a variety of lessons, I wish I paid more attention to at the beginning of the project:

Nothing matters as much as data quality

In the “premium” niche the mesoSPIM occupies, it is being compared to commercial instruments – prospective users have to be won over because many are skeptical that a custom instrument will fulfil their needs as well as a commercial instrument. To achieve this, example data has to be breathtakingly beautiful to speak for itself – it pays off to go the extra mile to ask around for the best and most challenging samples.

Pretend that every instrumentation project is an open-source project

I believe that nowadays, it is good scientific practice to adhere to open-source guidelines. Even if you are not planning to release the project – and there are many good reasons why – it helps to adopt an open-source mindset: split your project into reusable components and document everything as best as you can as early as you can. This makes equipment more reliable, experiments more reproducible and helps with knowledge transfer in the lab after you move on. I believe that PIs should encourage such best practices even though they appear to be a large time sink early on. And in case you are going to turn it into an open hardware project, most of your work towards release is already done! In the case of the mesoSPIM, I massively underestimated the time required to document everything – and it took me months to complete even a minimal version.

Communication is key

Biologists and physicists or engineers speak different languages – it can be surprisingly difficult for technology developers like myself to distill instrumentation specifications out of diffuse user requirements. Often, the unspoken message is “We can tell you it’s good data when we see it.” Under these circumstances, it is also difficult to convey the challenges of developing custom instrumentation back to users: a microscope might sit seemingly ready on the optical table, but requires time-consuming alignment. Hardware development is usually much faster than software development. The relationship between hardware costs and data quality is often not that clear. Be frank and make a concentrated effort to understand the needs of your users and help them to understand the challenges that you are facing. Also, don’t jump into conclusions too soon – the solution you are thinking of might not solve the actual problem your users are running into. Understand this process as a key part of your job as an open hardware developer and take your time.

Your target audience might not be what you think it is

Initially, I aimed the mesoSPIM initiative at people like myself – someone experienced in building custom microscopes who needs a custom high-performance light-sheet microscope. In reality, there is a layered audience: imaging facilities and their users, PIs who need a microscope for their lab, postdocs & PhD students who just want to use an instrument without having to “worry about the details”, and data scientists who process the images. I did not realize that the majority of people who would get in touch regarding this custom instrument are not well versed in optics and electronics. For example, I thought that most labs interested in a mesoSPIM would already have an optics lab, but many don’t and they need help to get such a lab started, for instance in selecting an optical table. I underestimated the associated challenges; starting such a lab often means getting a dedicated room – and space is at a premium in many institutions. Aspects like these led me to start developing a benchtop version of the mesoSPIM to target this audience better. In short, I thought I’m developing for engineers and physicists – in reality, I’m developing for neurobiologists, developmental biologists, pathologists and many other groups – most of whom do not care about how the microscope does what it does, but rather what they can do with it.

Usability over performance

In line with the previous aspect, often, features a technology developer is most excited about are those that do not improve your users’ day-to-day life with the instrument that much. You might be excited about getting the last bit of performance out of a custom instrument, but if this requires tuning a bewildering variety of parameters, users will not achieve that performance on their own. Complexity is scary – so shy away from fancy features in favor of things that are easy to understand, easy to use, and easy to fix. Aim for a clear alignment plan with a minimum number of degrees of freedom. Make an effort to improve the user interface of your software by watching users struggle with it.

Don’t be afraid to tell people to buy a commercial instrument instead

Many PIs interested in getting your instrument do not realize that the flexibility and capabilities of a custom microscope comes with a hidden cost far exceeding the budget required for the parts; someone has to understand the ins and outs of it and operate it. Some PIs are not familiar with custom optical instruments and think they can get a microscope on a relatively low budget within an aggressive schedule with an inexperienced team. Beware of the PI who thinks that a student will “learn it” because he or she is so “passionate”. In such cases, direct them to commercial vendors – they will be better off in the long term and you spare the students a lot of frustration. I think that open hardware should not be a fight for market share, but scientific impact.

Share, preprint, publish – and iterate often

Development cycles in industry often seem excessively long – but the only way a product can become mature enough for a market is by ironing out most of its teething problems. This process can take much longer than the initial proof-of-concept stage of product development. To arrive at reliable open hardware, it helps to realize that you will not learn what issues are present in your instrument, software, and documentation unless somebody else tries to copy it without your help and encounters problems. I suggest to share the instrument with selected labs long before a preprint goes online. Don’t worry about finding collaborators – it is often surprisingly easy to find them if your work tackles an unmet need in the community. Their feedback will refocus your development work on important issues. Moreover, at the time of submission, you can stress that your project has already been successfully shared with the community, which massively strengthens your manuscript – something that turned out to be beneficial for the mesoSPIM manuscript.

Open hardware is a global endeavor – plan and document accordingly

Nowadays, it should be possible to copy your hardware almost anywhere on the globe. Someone buying the same piece of hardware in a different country might encounter vastly different prices or might not be able to source the component at all. Prefer hardware vendors with established world-wide sales networks. Anticipate vendors and distributors going out of business or discontinuing product lines – plan to use alternative options for key components. Form strategic relationships with companies – often, they are highly excited about open hardware projects.

Nurture and enjoy the emerging community

Take time to support the community, plan workshops to help users copy and use your instrument. Understand that sharing software is much easier than sharing hardware – it requires a significant effort to train a new user to build the setup. Savor the moments when someone does something totally unexpected with your instrument – both acquiring cool data and extending the setup in surprising ways.

Fabian Voigt

Post-doctoral Researcher

Brain Research Institute

University of Zurich, Switzerland

(2 votes, average: 1.00 out of 1)

(2 votes, average: 1.00 out of 1)

I am thrilled to see your work on a new kind of microscope that is reflective multi immersion microscope which is relatively simpler to develop in laboratory environment. However, a question remains in my mind- how did you tune the correction plate everytime when you play with different medium between the mirror and the plate. Could you please elaborate me a bit on this part?